1. Gottwald AK680 (1,200 ton)

The Gottwald AK680 emerged around 1980 as one of the most powerful and pioneering lattice boom truck cranes ever built. Developed by Gottwald in Düsseldorf, Germany, the crane was designed to break new ground in mobile heavy lifting by offering crawler-like capacities on a roadable wheeled chassis—a rare feat at the time. The first AK680 unit was delivered to UK operator Scott Greenham, and later saw service with fleets such as Grayston, White & Sparrow and Sarens, showcasing its enduring value over decades.

With a maximum lifting capacity of 1,200 tonnes, the AK680 became a game-changer in the industry, capable of handling massive industrial components, bridge segments, and infrastructure modules that conventional truck cranes simply couldn’t lift. Its robust lattice boom and modular design reflected Gottwald’s engineering ambition and set a new benchmark for what truck-mounted cranes could achieve.

Though only a limited number were ever produced, the AK680’s influence runs deep. It laid the groundwork for the next generation of mobile heavy lift cranes and inspired design philosophies that persist to this day. Even after four decades, upgraded models like the AK680-3 continue to operate on major projects worldwide—a testament to the durability, versatility, and visionary design of this iconic machine.

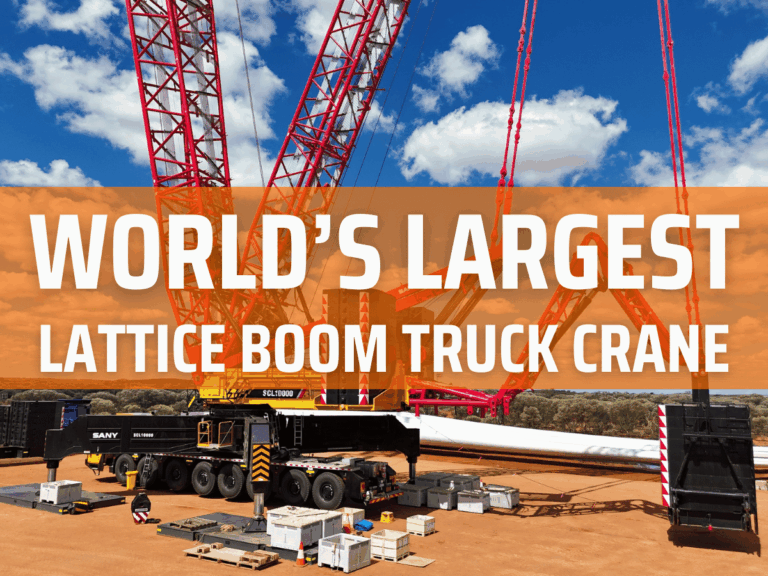

2. Sany SCL10000 (1,000 ton)

The Sany SCL10000, a powerful 1,000-tonne class lattice boom mobile crane, made its debut in August 2022, positioning itself as a key player in heavy lifting for the wind power sector. Developed for efficient transportation and high lifting performance, the SCL10000 is engineered to handle the demands of modern wind turbine erection—particularly those in the 6 MW range and beyond.

Initial Launch and Global Rollout

- China (August 2022):

The first unit of the SCL10000 was delivered to Beijing Baihua Hengshi Equipment Installation Engineering Co., Ltd., where it was immediately deployed for the installation of a 6.25 MW wind turbine, marking the crane’s official debut on the world stage. - Australia (Early 2023):

Leading heavy equipment distributor Tutt Bryant Equipment introduced the SCL10000 to the Australian market, utilizing its immense lifting capacity and on-site mobility for wind farm construction. This marked the first appearance of the model in the Southern Hemisphere. - Chile (Late 2023):

The crane arrived in Chile, becoming the largest-capacity Chinese-brand crane in the country. It was introduced to support the growing wind energy sector, particularly for the installation of sub-6 MW class turbines, demonstrating the crane’s international versatility and performance.

With its lattice boom design, modular transportability, and industry-leading lifting performance, the SCL10000 has quickly established itself as a strategic solution for utility-scale wind energy projects across multiple continents.

3. Gottwald AK 850 (850 ton)

In the world of heavy lifting, few machines have left as lasting an impression as the Gottwald AK 850. Developed during the early 1980s by the renowned German manufacturer Gottwald, the AK 850 emerged at a time when demand was growing for cranes that could not only lift massive loads but also travel to the job site under their own power. With its imposing 10-axle carrier and an 850-ton maximum lifting capacity, the AK 850 broke new ground by merging the brute strength of a crawler crane with the flexibility and mobility of a roadworthy truck crane. It quickly became a favored solution for heavy industrial projects, including power plant construction, refinery work, and precast bridge installations, where both reach and capacity were critical.

What made the AK 850 particularly noteworthy wasn’t just its lifting power, but its adaptability. With a main boom that could extend beyond 110 meters and the option of a luffing jib reaching nearly 95 meters, the crane was capable of tackling complex, high-elevation lifts that would challenge even modern machines. Its dual-engine setup—one for travel and another for the superstructure—ensured it could operate independently and efficiently, while its massive outrigger base provided the stability needed for safe heavy lifting. Though production was limited and the crane is now considered a legacy model, the AK 850 remains a reference point in the evolution of high-capacity mobile cranes. Its continued recognition among crane professionals is a testament to the foresight of its designers and the enduring impact of its engineering.

In the world of heavy lifting, few machines command the kind of respect earned by the Gottwald AK 850. Born in an era when engineering pushed the limits of what mobile cranes could achieve, the AK 850 was not just a feat of German precision—it was a statement of capability. With an 850-ton lifting capacity and a road-going chassis beneath a towering lattice boom, this crane redefined mobility and power for its generation. Decades later, it still stands as a symbol of what could be accomplished when bold design meets practical execution in the field.

4. Liebherr LG 1800-1.0 (800 ton)

The Liebherr LG 1800-1.0 officially debuted in December 2023, marking the arrival of a next-generation 800-tonne class mobile lattice boom crane. Positioned as the successor to the long-revered LG 1750, this new model merges high-capacity lifting with the flexibility of a mobile wheeled chassis, targeting demanding applications in wind turbine erection and complex industrial construction.

Launch Timeline and Rollout

- December 2023: Liebherr formally announced the LG 1800-1.0, introducing it as the next evolution of its mobile lattice boom line.

- Early 2024: The crane entered active service, with the first deliveries and job deployments beginning in the first half of the year.

- Late 2024: Among the first customers was Lewandowska, a Polish heavy lifting firm that took delivery of the model for major project use.

Key Features and Market Purpose

The LG 1800-1.0 is engineered to lift up to 800 tonnes, matching the capabilities of its crawler sibling, the Liebherr LR 1800-1.0, while offering the road mobility and speed advantages of a wheeled carrier. It retains the lattice boom design for heavy-duty lifting performance and introduces updated systems for transport, rigging efficiency, and site adaptability.

Serving as a direct replacement for the LG 1750, the LG 1800-1.0 brings increased lifting power, modern design upgrades, and improved efficiency for high-reach wind turbine installations and other large-scale industrial lifts.

With its hybrid identity—combining crawler-grade lifting strength with mobile crane convenience—the LG 1800-1.0 quickly became a standout choice for contractors needing high capacity and flexible deployment in a single package. Its 2024 rollout marks a new benchmark in Liebherr’s mobile lattice boom offerings.

5. Liebherr LG 1750 (750 ton)

When Liebherr unveiled the LG 1750 at the Bauma trade fair in Munich back in 2004, it marked the beginning of a new chapter in heavy lifting. This wasn’t just another crane—it was a machine that would go on to define an era, particularly in the booming wind energy sector. With its clever combination of crawler-class lifting power and road-going mobility, the LG 1750 quickly became a mainstay on construction sites around the world.

At its core, the LG 1750 was designed to do something most cranes couldn’t: deliver 750 tonnes of lifting capacity while remaining road-mobile. Mounted on an eight-axle chassis with smart rear-axle steering, it could be transported to job sites faster and more economically than traditional lattice boom crawler cranes. Once on site, it drew on the same powerful boom and upper structure as the LR 1750, giving it serious lifting muscle without the need for crawler tracks.

This unique hybrid of mobility and might made the LG 1750 especially well-suited for the wind turbine installations that were rising in both height and complexity throughout the 2000s and 2010s. The crane’s ability to reach hoisting heights of up to 193 meters, paired with its strong load chart, positioned it perfectly for erecting tall turbines, as well as handling major components in industrial plants and infrastructure projects.

But Liebherr didn’t stop there. As turbines grew taller and heavier, the LG 1750 evolved too. It received a major upgrade with the SX boom system, designed to increase lifting capacity and improve performance under higher wind loads. This enhancement gave the crane extended relevance in a rapidly changing market, allowing it to keep pace with new turbine generations and lifting challenges.

For nearly two decades, the LG 1750 proved itself as a reliable workhorse—fast to mobilize, powerful in action, and versatile across industries. From wind farms and petrochemical plants to bridge construction and modular lifting, it earned its place as one of the most trusted lattice boom mobile cranes of its time.

That legacy was carried forward in 2024, when Liebherr introduced the LG 1800-1.0, the official successor to the LG 1750. Building on its predecessor’s foundation, the new model brought increased capacity—up to 800 tonnes—and was tailored to meet the demands of 180-meter hub height turbines and future-ready wind projects.

Even as newer models take center stage, the LG 1750 remains a symbol of engineering ingenuity—a crane that bridged mobility and strength at just the right time, helping lift a generation of energy infrastructure into place.

6. Demag TC 2800-1 (600 ton)

The Demag TC 2800‑1 emerged as one of Demag’s most capable heavy‑duty lattice boom truck cranes, essentially bridging the gap between traditional crawler cranes and fully all‑terrain models. Built at a time when Demag was part of the Terex family (with mobile crane production taking place primarily in Zweibrücken, Germany), the TC 2800‑1 was designed to offer robust lifting performance without the transport and site setup demands of larger crawler units. Its 600‑tonne lifting capacity at a 6 m radius positioned it at the upper end of mobile lattice boom cranes, making it an attractive solution for the kind of heavy industrial, infrastructure, and wind power erection work where both strength and mobility mattered.

What set the TC 2800‑1 apart was its combination of power, reach, and transportability. With a standard lattice boom extendable up to around 138 m (and a system length approaching 192 m when assembled), the crane was capable of handling tall lifts and significant horizontal reach without sacrificing stability or safety. Its lattice structure kept deadweight lower than comparable telescopic alternatives, while the large outrigger base contributed to excellent lifting capacity throughout its working range. Engine choices and control systems of the era emphasized reliability and operator familiarity, helping the TC 2800‑1 build a reputation as a machine that was both rugged in performance and practical in everyday operation.

Over its production life (with many units built between the late 1990s and the early 2010s), the TC 2800‑1 carved out a niche for itself in markets where heavy lifts were required but the full footprint and transport complexity of crawler cranes weren’t desirable. While the Demag name later transitioned through Terex ownership and eventually into the Tadano era, cranes like the TC 2800‑1 remain a testament to the company’s long history of blending German engineering with practical field performance.

7. Demag TC 1200 (600 ton)

The Demag TC 1200 holds a special place in the evolution of lattice boom truck cranes as one of Demag’s early and successful heavy‑capacity road‑going cranes. Introduced in the early 1970s, the TC 1200 was developed when Demag was expanding its range of lattice boom cranes designed to deliver high lifting power without the transport and setup complexity of crawler cranes. With a maximum rated capacity in the 250–350 tonne range and the ability to accommodate boom lengths up to around 90 m with additional jib arrangements, the TC 1200 was engineered to meet the demanding needs of heavy industrial construction projects, including petrochemical plants and structural steel installations.

Built on a robust 7‑axle, 12×4 truck carrier powered by a KHD BF12L 413 diesel engine producing around 310 kW (420 hp), the crane combined substantial lifting strength with mobility that allowed it to travel between sites under its own power. The lattice boom design kept deadweight down while providing excellent structural strength, and the crane could be equipped with a variety of attachments—such as the innovative Superlift auxiliary counterweight system introduced by Mannesmann‑Demag in the mid‑1970s—to boost lifting performance up to around 600 tonne in select configurations.

Historically, the TC 1200 exemplified Demag’s engineering direction during the 1970s and 1980s, a period when the company was part of the larger Mannesmann group, which invested in expanding mobile crane capabilities as global infrastructure and energy projects grew. The TC 1200 served as a dependable workhorse for decades, and its success helped cement Demag’s reputation as a builder of heavy‑duty lattice boom truck cranes before the industry shifted increasingly toward all‑terrain and hydraulic models.

8 Liebherr LG 1550

The Liebherr LG 1550 stands as a testament to Liebherr’s long‑standing tradition of engineering robust and versatile lattice boom mobile cranes. Introduced in the late 1990s and produced into the early 2000s, the LG 1550 was designed to serve the mid‑to‑high‑capacity segment of Liebherr’s “LG” lattice boom lineup. While Liebherr is a global leader in crane manufacturing with a history dating back to 1949, its mobile lattice boom cranes like the LG 1550 represent a focused effort to blend high lifting power with on‑road mobility—an approach that helped solidify Liebherr’s reputation in heavy industrial, infrastructure, and wind energy projects worldwide.

With a maximum lifting capacity of around 550 tons, the LG 1550 brought substantial strength to a road‑legal 8‑axle chassis, offering project teams the ability to relocate between sites without the transport complexity of larger crawler cranes. Its lattice boom could reach generous heights—commonly up to over 100 meters in main boom configurations—and, when fitted with luffing or fixed jibs, enabled lifts at extended radii suitable for tall structures and wind turbine assemblies. This flexibility made it highly competitive in its class; in some configurations, it even rivaled cranes traditionally larger in size, all while requiring less site preparation and setup time compared to crawler alternatives.

During its production life, the LG 1550 carved out a niche among contractors and heavy‑lift specialists who needed both capacity and mobility. Its enduring presence on job sites well into the 2010s and beyond underscores its reliability and adaptability—qualities that have become hallmarks of Liebherr’s lattice boom cranes. As part of the broader Liebherr family of lifting solutions, the LG 1550 helped bridge the evolution from classic heavy lattice boom designs toward the more modern, modular cranes in Liebherr’s current lineup, reflecting the company’s ongoing innovation in meeting the demands of complex lifting challenges.