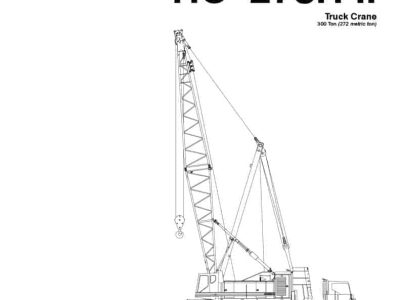

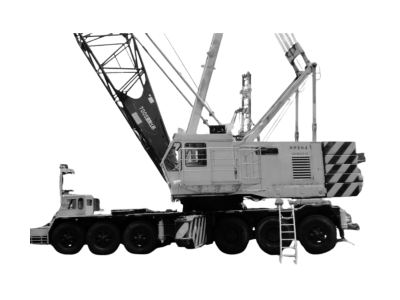

P&H 9150-TC

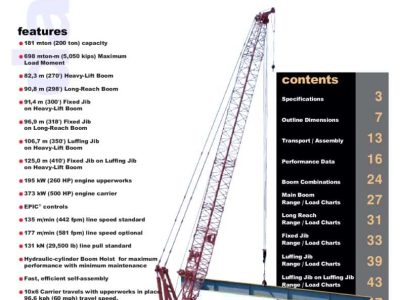

The P&H 9150-TC is a high-capacity lattice boom truck crane mounted on an 8×4 truck carrier, delivering a maximum lifting capacity of 150 tons. It features a modular heavy-duty boom extendable up to 51.82 meters, hydraulic outriggers, and a Mitsubishi 8DC60C diesel engine. With a fully hydraulic control system and a working weight of 220,460 lbs, this crane is designed for heavy-duty lifting in both infrastructure and industrial applications.

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

The P&H 9150-TC lattice boom truck crane is a powerful and versatile lifting machine developed to meet the demands of large-scale construction and industrial projects. It is built on a robust P&H KS-150 truck carrier with an 8×4 axle configuration, designed to provide stability, mobility, and ease of transport over public roads. Weighing in at approximately 100,000 kg (220,460 lbs), including a heavy-duty boom and a 65-ton swivel hook block, this truck crane exemplifies P&H’s engineering legacy for reliability and performance.

At the heart of the 9150-TC is a Mitsubishi 8DC60C, 8-cylinder diesel engine producing 230 horsepower at 2,000 rpm, which powers the crane’s upper machinery. A Niigata CBG5C-100, 3-stage torque converter with a tailshaft governor ensures smooth and responsive operation across lifting functions. Fuel capacity is 416 liters (109.9 gallons), supporting long-duration jobs without frequent refueling interruptions.

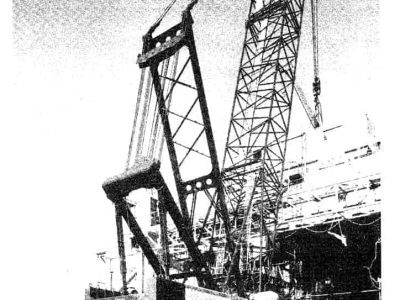

This crane boasts a modular tubular high-tension steel boom. The heavy-duty boom configuration is pin-connected and extendable up to 51.82 meters (170 feet), with a base boom section measuring 7.62 meters. A lighter-duty version extends up to 88.39 meters (290 feet) using narrower sections. Both boom types use open throat sheave assemblies mounted on anti-friction bearings with standardized pin spacing of 616 mm (24¼”).

For additional reach, the 9150-TC supports optional boom inserts ranging from 3.05 to 12.19 meters, and a pin-connected jib system up to 18.29 meters (60 feet). The jib includes a single boom point sheave and can be mounted with a variety of hook blocks, including a 150-ton capacity with six sheaves, a 65-ton with three, a 25-ton with one, and a 13.5-ton ball hook.

The boom and main drum assemblies use planetary gear drives and multiple braking systems for safe and precise handling. The hoist system includes band-type brakes with hydraulic fail-safes and spring-set mechanisms. Hoisting speeds are rated at 52 m/min (170.6 fpm), while lowering speeds reach up to 30 m/min (98.4 fpm), with a maximum line pull of 21 m/min on the boom hoist. The rotating upper works are driven at 2.8 rpm, supported by a 40-roller live circle swing bearing system and powered via Magnetorque clutches.

For safe operation and stability, the 9150-TC is equipped with eight double-acting hydraulic outriggers controlled by solenoid valves. Outrigger beams are made from welded high-tensile steel, and the carrier is designed with full air brakes, recirculating ball screw power steering, and laminated spring suspension. The crane offers a maximum road speed of 65 km/h and handles grades up to 36%.

Counterweights are provided in three sections with a total removable weight of 32,600 kg (71,870 lbs), mounted with ease using boom rigging. The crane’s standard working configuration includes all hydraulic riggers and equipment, with a typical road transport weight of approximately 35,500 kg (78,265 lbs).

The P&H 9150-TC remains a respected machine in the class of large truck cranes, valued for its robust boom configurations, advanced lifting technology, and reliable Mitsubishi powertrain—making it suitable for bridge building, refinery work, and general heavy construction tasks.

Latest News

Top 10 Largest Rough Terrain Crane In The World

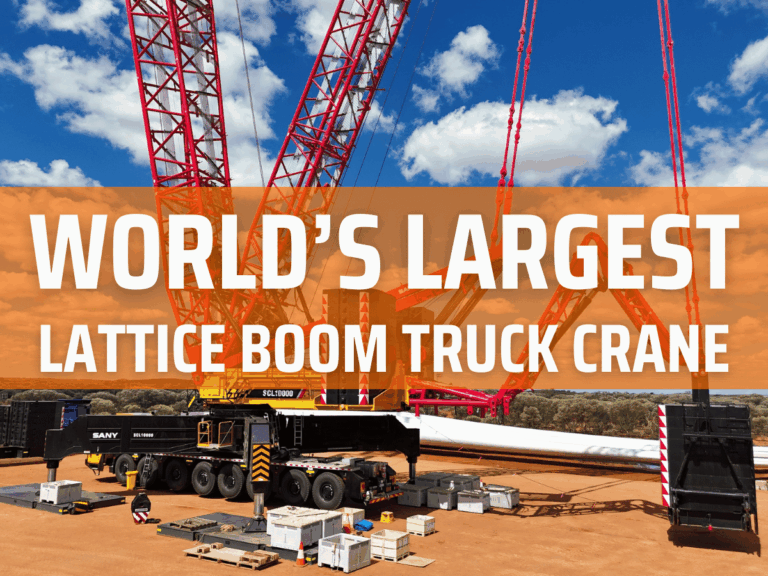

Top Largest Lattice Boom Truck Crane In The World

Reviews

There are no reviews yet.