Tadano GR800EX

The GR800EX (also known as GR1000XL in North American markets) is one of the GR series rough terrain crane developed by Tadano for international markets in 2011.

Product Description

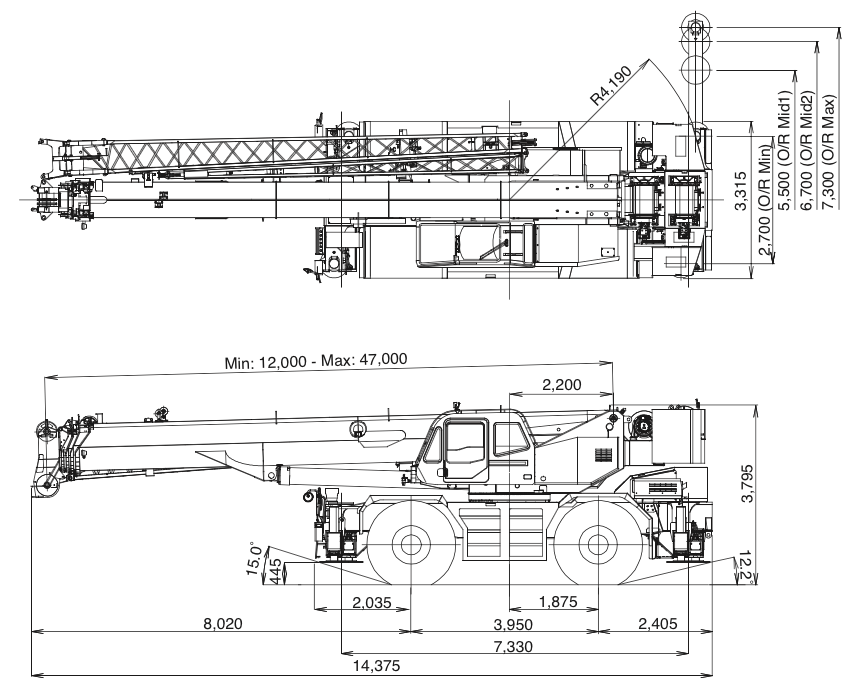

The crane is rated 80-tonne at 3 metres and comes with a 47.0 metres, 5-section main boom. The rounded boom is made of high tensile steel, which allows increased boom strength while a decrease in its self-weight. The 5-section operates on a partially synchronised boom system that consists of a double acting telescoping cylinder, extension cables and retraction cable. This new boom design could be found as well in the GR600EX and GR800EX in the series. In addition, there are two telescoping modes for the main boom – Mode [I] for normal operation that extend the 2nd section followed by synchronised extension of the 3rd, 4th and 5th sections while Mode [II] extend the synchronised extension of 3rd, 4th and 5th sections follow by 2nd section independently. The latter is used when stability is more important than performance.

In addition, the 80-ton rough terrain crane can be equipped with an optional 2-staged bi-fold lattice type jib of 10.1 / 17.7 metres, giving it a maximum lifting height of 64.4 metres. The jib can be offset at 3.5, 25, 45 degrees. Furthermore, the GR500EX is equipped with an assist cylinder for the jib, which helps to increase work efficiency when mounting and stowing of the jib.

The crane is powered by a 4-cycle, turbocharged and after-cooled 6-cylinder inline, direct injection water-cooled Mitsubishi 6M60-TL or Cummins QSB 6.7 EUROMOT 3b (Europe specs) that has a maximum output of 200 kW at 2,600 rpm and 194 kW at 2,500 rpm respectively.

Dimensions of GR800EX. Click photo to enlarge.

Crane Management Through Tadano’s HELLO-NET

Tadano has incorporated their own management system on the new GR series which allows crane owners to manage their Tadano’s fleet via internet easily. The system provides a day-to-day work history that includes operational status, mileage and remaining fuel. It can be also used to determine the location of the crane based on either the location where cranes PTO is activated (more than an hour) or the final location from which GPS receiver on a given day. Lastly, it can also help to provide maintenance information for periodical parts replacement and inspection schedule. (This function is currently available in selective countries)

Check out Tadano’s HELLO-NET promotion video here.

Environment-Friendly Functions.

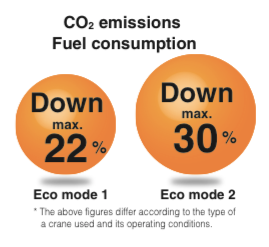

Tadano has designed the crane to reduce the impact on the environment by substantially reducing fuel consumption and CO2 emission.

Fuel Monitoring System – The AML screen has been integrated for monitoring of fuel consumption which constantly displays fuel consuming during the period of crane operation, standby and travelling. These data can be displayed as fuel consumption history to use for controlling crane operating condition.

Based on a study done by Tadano, the results show that approximately only 40% of the time the crane was in operating mode while 60% it was in a non-operating mode (in a state of standby) and thus two functional devices have been developed to reduce fuel consumption.

Eco Mode System – It helps to control the maximum engine speed during crane operation. There is two mode – Mode 1 and Mode 2 decrease CO2 emissions and fuel consumption to a maximum of 22% and 30% respectively. In addition, it also helps to reduce the noise level when the crane is in operating mode.

Positive Control System – The system effectively control the quantity of the hydraulic pump discharge at the time of crane operation in response to the amount of movement applied by the operating lever. By keeping the hydraulic pump discharge to a minimum, it helps to reduce up to a maximum of 20% on the CO2 emissions and fuel consumption.

Control of Asymmetric Extension Width Of Outriggers

One of the main features of Tadano’s new AML-C is when the crane is operating with asymmetric outriggers extended, the system automatically detects the extension width of outriggers at all four points and define the maximum possible working condition for each area. When the boom slew from a direction where outriggers are full extended to an area which outriggers are intermediately extended, the AML-C automatically detects the motion and display the maximum allowable capacity and bring the slew to a slow stop before reaching its limits of the allowed capacity. This helps to provide additional safety to the operation while minimising operating risks when operator is not aware.

Reviews

Products You Might Be Interested

Related products

-

Tadano GR550EX

0 out of 5Read more -

Terex RT 90

0 out of 5Read more -

Kato KR500

0 out of 5Read more -

Kato KR10H-L2 (MR100Lsp-V)

0 out of 5Read more -

Kato KR50H-L (SL600)

0 out of 5Read more -

Tadano GR250N-3

0 out of 5Read more -

Grove RT550E

0 out of 5Read more -

Kato SR700L

0 out of 5Read more -

Tadano GR700EXL

0 out of 5Read more -

Kato KR20HL (SR200R)

0 out of 5Read more -

Grove RT530E-2

0 out of 5Read more -

Kobelco RK250-3 (Panther 250)

0 out of 5Read more

Reviews

There are no reviews yet.