The Link-Belt LS-218H is a proven 100-ton class hydraulic crawler crane built for performance, versatility, and ease of transport. Featuring a welded steel frame with a robust turntable bearing system and removable hydraulic side frames, this crane offers a balance between strength and transportability. The crawler undercarriage includes 36-inch wide track shoes, hydraulic track adjustment, and nine lower and three upper rollers per side. With a maximum travel speed of 0.8 mph and gradeability of 30%, the LS-218H can confidently navigate job sites.

Powering the LS-218H is a Mitsubishi 6D24-TEB six-cylinder diesel engine rated at 263 hp (196 kW) at 2,000 rpm, with a peak torque of 746 ft-lb at 1,400 rpm. The engine is supported by a 119-gallon fuel tank, and all functions are driven hydraulically by a series of pumps with pressure capacities up to 4,000 psi. The hydraulic system includes dual variable displacement pumps for main functions, along with additional pumps dedicated to swing, jacking, and pilot controls.

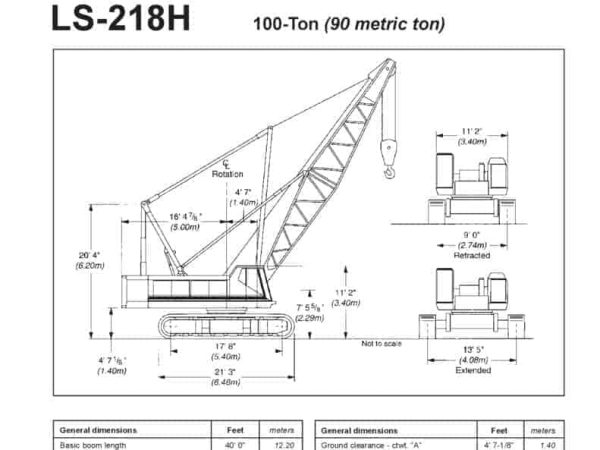

The LS-218H supports both angle and tubular booms. The basic boom length is 40 ft, and it can be extended in 10, 20, or 30 ft increments up to a maximum of 200 ft for the tubular boom and 180 ft for the angle boom. Boom connections use in-line tapered pins, and the structure includes open-throat top sections. Tubular booms are constructed with 3-inch OD chords, while the angle boom uses 4-inch x 4-inch chords. Boom hoisting is managed by a 26-foot live mast and a 10-part wire rope reeving system.

Load handling is accomplished with individual axial piston motors for the main, auxiliary, and optional third drums. The front and rear hoist drums are 21.5 inches in diameter and grooved for 1-inch rope, with standard freefall clutches and automatic braking systems. The third drum supports pile driving and luffer applications, with controlled free spooling available. Load hoisting speed varies by rope layer, ranging from 102 fpm to 315 fpm, with line pull starting at 54,012 lb on the first layer.

The swing system includes two-speed operation (1.3 and 2.5 rpm), with automatic braking and mechanical locking. The operator cab features ergonomic controls, a full suite of gauges and indicators, and climate control for operator comfort. Safety systems include anti-two-block protection, load indicators, optional rated capacity limiter (RCL), and drum rotation indicators.

For extended lifting capabilities, the LS-218H can be equipped with a tubular jib ranging from 30 to 75 ft, offsettable to 0°, 15°, or 30°, and featuring its own wire rope sheave systems. With a complete counterweight setup (46,700 lb), the LS-218H reaches a working weight of approximately 169,650 lb, providing the foundation for heavy lifting tasks across construction, industrial, and civil engineering environments.