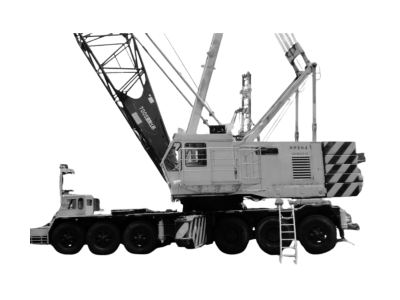

P&H 9150

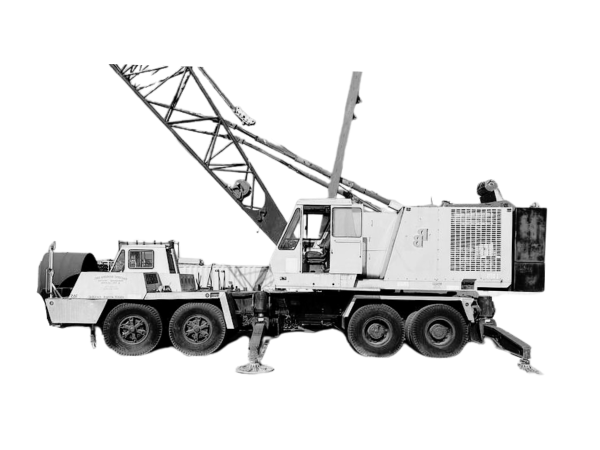

The P&H 9150 is a heavy-duty lattice boom truck crane designed for high-capacity lifting operations, with a rated lifting capacity of up to 150 tons. Mounted on a robust 8×4 truck carrier with 12 wheels and powered by a Cummins diesel engine, the crane features a tubular high-strength alloy boom extendable to 250 feet and jib options up to 60 feet. Known for its powerful drivetrain, full-flow hydraulic systems, and extensive boom and jib configuration flexibility, the 9150 is well-suited for demanding infrastructure and industrial applications.

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

The P&H 9150 lattice boom truck crane is a high-capacity, truck-mounted lifting machine engineered to handle substantial loads across a variety of heavy-duty applications. With a rated lifting capacity of up to 150 tons (136 metric tons), the 9150 is built to deliver reliable and efficient performance on demanding construction sites, particularly in industrial, civil, and bridge-building projects.

The crane is built on a durable 8-wheel, 4-axle truck carrier (P&H KS-150) featuring 12 tires and 4-wheel drive. Its carrier is powered by a Cummins NTC-300 or optional NTCC-350 turbocharged diesel engine, delivering up to 350 HP at 2100 RPM. This is coupled with a Fuller RTLF-12515 15-speed forward / 3-speed reverse transmission for precise control and road handling. The carrier includes power steering (Ross worm and roller type), air brakes, and a rear planetary bogie axle with a 9.48:1 total ratio for traction. It can reach highway speeds and is designed to be street legal, offering a practical blend of mobility and lifting power.

The upper structure is powered by a Cummins V903, 8-cylinder diesel engine rated at 255 HP gross at 2400 RPM, with a net output of 179 HP at 1285 RPM via a Twin Disc CO-10,000 MS-260 three-stage torque converter. This engine supports all crane operations, including boom hoist, swing, and load drums, through a hydraulic system that delivers 1500 PSI (105 kg/cm²) of pressure, providing fast, smooth, and responsive control.

The boom system is a lattice-type, open-throat design fabricated from round tubular 100,000 PSI yield-strength alloy steel chord members and reinforced with contour-cut tubular lacings. The base boom consists of a 25-foot tapered section with a mechanical pendulum-type angle indicator, and a heavy-duty 25-foot tip section with five offset sheaves on roller bearings. The crane’s boom is modular and extendable through optional insert sections in 10′, 20′, 30′, and 50′ lengths to a maximum reach of 250 feet (76.2 meters). For long-range applications, a 35-foot tip section with two or three sheaves is available, enabling extended lifts from 260 to 270 feet (79.3 to 82.3 meters).

Optional jibs up to 60 feet (18.2 meters) can be attached for additional versatility. These jibs are also of lattice construction, made from tubular alloy chord members and designed with high-tensile pin connections. The jib system uses 18″ (457 mm) sheaves for 1” wire rope (18:1 rope ratio), suitable for two-part hoist operations.

The hoisting system utilizes independent twin work-motion systems with load drums mounted in tandem, driven by clutch and brake assemblies and supported by large-diameter drums. Boom hoist drums are also driven by planetary gear drives with locking pawls and fail-safe brakes. The hoisting performance is robust, with a maximum line pull of 15,095 lbs (6,845 kg) on 21:1 rope ratio, and line speeds ranging from 18 to over 80 feet per minute depending on configuration. A third drum is optionally available for clamshell or dragline work, or specialized hoisting requirements.

The swing system uses the Magnetorque system—a proven, low-maintenance electromagnetic clutch drive—delivering a maximum swing speed of 3.94 RPM. The swing gear uses 139 internal cut teeth, with braking handled by an 18″ (457 mm) drum brake.

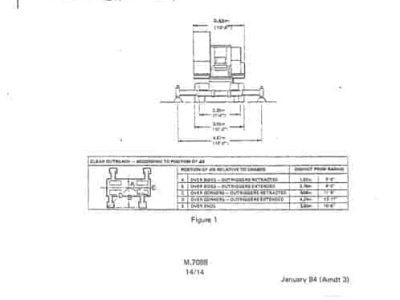

The carrier is equipped with eight double-acting hydraulic outriggers operated from the control cab, providing both vertical and horizontal extension for enhanced stability. Optional 30″ diameter aluminum floats (up to four) are available for soft ground conditions. The hydraulic system also supports boom and jib erection, allowing self-assembly of the crane’s superstructure without the need for auxiliary lifting equipment.

Safety features include dual boom backstops with shock absorbers, boom hoist kickout, anti-two-block sheave guards, and full instrumentation in the cab. The operator’s cab is a modular, insulated steel enclosure with all-weather features, including heater, defroster, and optional air conditioning. It houses a full complement of gauges, indicators, and hydraulic controls for precise lifting operation.

In terms of weights, the complete machine including base boom and 65-ton hook block weighs approximately 163,857 lbs (74,323 kg). The counterweight system is modular, with a total of 64,000 lbs (29,030 kg) split into removable upper and lower sections to simplify transport and setup.

The P&H 9150 stands out as a flagship model for large-capacity mobile lifting, with unmatched boom length flexibility, reliable Cummins powerplants, and rugged construction. It was developed to handle the toughest hoisting jobs while maintaining the mobility and setup advantages of a truck-mounted crane system.

Latest News

Top 10 Largest Rough Terrain Crane In The World

Top Largest Lattice Boom Truck Crane In The World

Reviews

There are no reviews yet.