FMC Link-Belt HC-258

The Link-Belt HC-258 is a high-capacity truck-mounted lattice boom crane designed for heavy-duty lifting applications. With a maximum lifting capacity of 125 tons, modular boom extensions up to 300 feet, and multiple jib configurations, the HC-258 offers exceptional versatility and power for large-scale construction, industrial, and infrastructure projects.

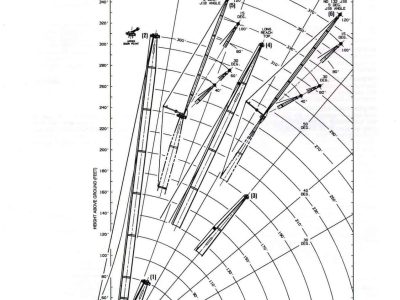

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

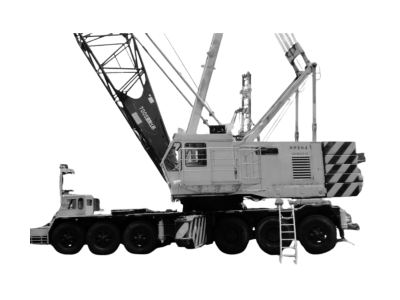

The Link-Belt HC-258 is a rugged and reliable 125 US-ton lattice boom truck crane, developed for heavy-duty lifting operations where high reach, large capacity, and job site flexibility are essential. Built on a FMC 288” (7.32 m) wheelbase carrier, this machine combines a strong structural platform with the flexibility of modular boom and jib systems, making it a staple on demanding construction and infrastructure job sites.

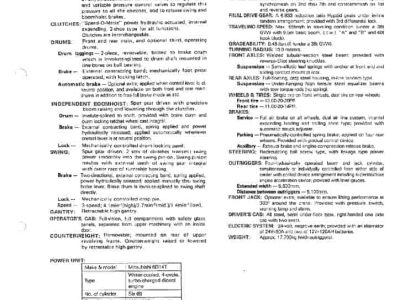

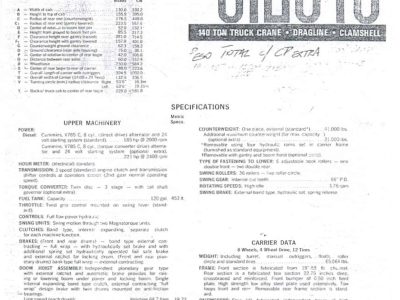

The crane features a hydraulic outrigging system, with a single jack at the front and dual jacks at the rear, all mounted on roller tracks for easy setup and retraction. The steel-framed carrier is powered by a Cummins KT-450 diesel engine, which delivers 450 brake horsepower at 2,100 RPM, paired with a full manual transmission and air-actuated disc clutch. This configuration provides strong performance for both on-road travel and on-site maneuvering. It has a maximum road speed of 40.3 mph, and its climbing ability is suitable for grades up to 0.81 MPH at 46.6%, fully loaded.

The main boom of the HC-258 uses tubular and lattice construction, offering both strength and light weight. The standard boom system consists of modular tapered and hammerhead sections, which can be configured to reach a maximum main boom length of 300 feet (91.44 m) using “AB” upper counterweights. The standard basic boom section is 40 feet, while base and straight extensions are available in lengths of 10, 20, 25, 30, 40, and 50 feet, all centerline-reinforced to maintain integrity during extended lifts. The boom tip sheave is designed to accommodate high line loads with anti-friction sheaves and large boom angles.

The jib system includes 30-foot basic jib sections and can be extended up to a maximum 70 feet (21.35 m) using 20-foot extensions. All jib sections can be mounted at 5°, 15°, or 25° offsets, giving the HC-258 remarkable reach and flexibility in complex lifting situations. A jib mast measuring 17 feet 10 inches is standard, incorporating two deflector sheaves and equalizer sheaves for main and auxiliary hoisting lines.

The upper machinery includes two main drums and an optional third drum, all equipped with anti-friction bearings. Standard line pull is up to 35,000 lbs (15,876 kg) on the front drum and 37,500 lbs (17,010 kg) on the rear drum, operating at line speeds up to 165 ft/min (50.29 m/min) depending on the setup. These figures are based on the General Motors 8V-71N engine configuration but are consistent with the performance from the Cummins NT-855-C310 as well. Planetary drive options are available for applications requiring higher speed or power load lowering.

The Speed-o-Matic hydraulic system provides a reliable and responsive control interface. Operating pressure is distributed to all hydraulic functions through an accumulator and pressure-regulated valves, ensuring consistent performance. Control is via 2-shoe hydraulic clutches for all major functions, with modulation for precise hoisting, boom swing, and load lowering.

The fully enclosed operator’s cab is ergonomically designed, equipped with full instrumentation, a heater/defroster, adjustable seat, and modular view windows. The standard environmental cab setup improves visibility and safety, especially when handling extended lifts with long boom configurations.

Additional key features include a retractable gantry for boom and mast support, boom angle indicators, and jib stops to ensure safe and controlled operations. The counterweight system can be customized based on boom length and working radius, with up to 70,000 lbs (31,752 kg) of counterweight possible in configurations using both “A” and “B” weights.

In summary, the Link-Belt HC-258 is a premium lattice boom truck crane designed for 125-ton capacity operations. With its modular boom extensions, jib adaptability, advanced hydraulic control system, and powerful diesel drivetrain, it remains a trusted choice for contractors working on bridges, power plants, high-rise buildings, and other complex lifting operations.

Latest News

Top 10 Largest Rough Terrain Crane In The World

Top Largest Lattice Boom Truck Crane In The World