XCMG XGC28000

The XCMG XGC28000 is a 2,000-ton crawler crane, engineered for ultra-heavy lifting applications in nuclear power, wind energy, and the chemical industry. First showcased at Bauma China 2010 in Shanghai, it drew global attention as China’s response to the world’s most powerful cranes. The crane features a maximum load moment of 28,000 ton-meters, a working radius of 14 meters (46 feet), and a maximum boom + jib length of 156 meters (512 feet). With dual-engine technology, a wireless remote control system, and advanced counterweight mechanisms, the XGC28000 sets new benchmarks for precision, power, and efficiency in heavy lifting. It has already broken lifting records, including a 1,340-ton hydrocracking reactor lift at Sinopec’s Quanzhou refinery in 2009, proving its exceptional capabilities in real-world applications.

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

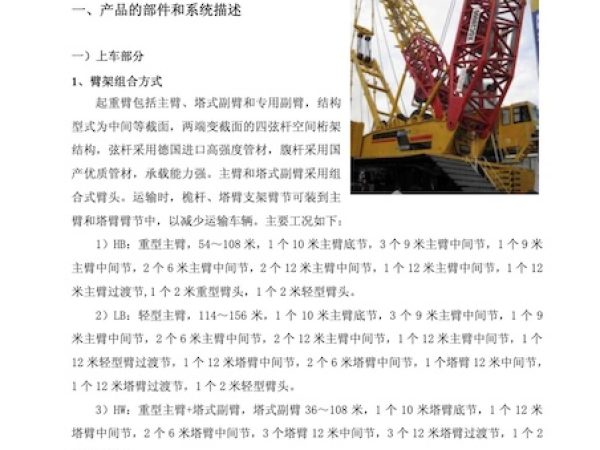

The XCMG XGC28000 represents a major milestone in China’s heavy lifting industry, marking XCMG’s entry into the ultra-heavy crawler crane market. First unveiled at Bauma China 2010, it was designed to meet the growing demands of large-scale infrastructure, nuclear power plant construction, wind turbine assembly, and chemical industry lifting requirements. With a maximum lifting capacity of 2,000 tons and a staggering load moment rating of 28,000 ton-meters, it competes with the world’s most powerful cranes.

Prototype Testing & Innovation

The XGC28000 showcased at Bauma China was the first prototype, reflecting XCMG’s commitment to rigorous testing and quality assurance. The crane underwent an extensive six-month testing phase in 2011 to meet the industry’s highest standards of performance, safety, and reliability.

One of the key advancements in the XGC28000 is its dual-engine, dual-power real-time distribution intervention system. It incorporates two V-type 8-cylinder Mercedes-Benz engines, conforming to strict emission standards. The system allows for switching between single and dual-engine operation, optimizing fuel efficiency, safety, and power output based on lifting requirements.

Optimized for Heavy-Duty Applications

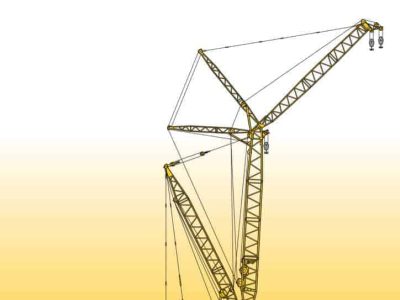

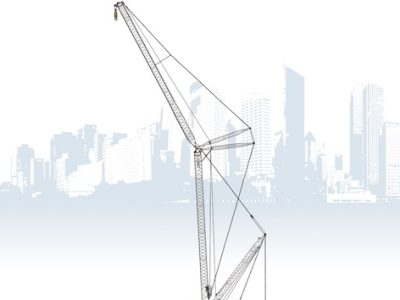

Designed for demanding lifting scenarios, the XGC28000’s main boom and jib configuration reach 156 meters (512 feet), offering unparalleled reach and flexibility. The hydraulic superlift counterweight system automatically adjusts its radius based on the lifting load, ensuring optimized stability and lifting efficiency.

To enhance operator control and comfort, the XGC28000’s spacious cab includes:

Power supply for on-site needs.

Frequency-converting air conditioning for climate control.

A refrigerator and foldable bunks, providing a comfortable working and resting environment.

Adjustable seats and expanded viewing angles, improving precision and safety during operations.

The crane also features an electro-hydraulic proportional control system, which enables stepless speed regulation, allowing for highly accurate lifting movements.

Wireless Remote Control & Advanced Technology

The XGC28000 is equipped with a state-of-the-art wireless remote control system, allowing operators to execute precise lifts from a distance, minimizing the need for auxiliary personnel. Additionally, it features:

A six-row axial roller heavy-duty slewing bearing, co-developed with Germany’s Rothe Erde, ensuring smooth, high-load rotation.

A split turntable design with a hydraulic synchronous power pin, making the structure compact and easy to assemble.

Two large color screens for system monitoring, ensuring real-time tracking of crane performance and safety parameters.

Record-Breaking Lifting Milestones

The XGC28000 has already set multiple records, proving its immense lifting power:

September 2009 – Sinopec’s Quanzhou Refinery Base (China): The XGC28000 lifted a 1,340-ton hydrocracking reactor using a 60-meter heavy-duty boom, 340-ton turntable counterweights, 111-ton crane body counterweights, and 640-ton superlift counterweights at a 30-meter superlift radius. This lift broke its previous record of 958 tons in Maoming, Guangdong.

Future of Heavy Lifting

The introduction of the XGC28000 at Bauma China was not just an expansion of XCMG’s product line—it marked a leap forward in heavy lifting technology. With its innovative powertrain, adaptive counterweight system, remote-controlled operations, and unmatched load capacity, the XCMG XGC28000 is a game-changer in the global crane industry, setting new standards for efficiency, power, and safety in large-scale construction and energy projects.

Latest News

Top 10 Largest Rough Terrain Crane In The World

Top Largest Lattice Boom Truck Crane In The World