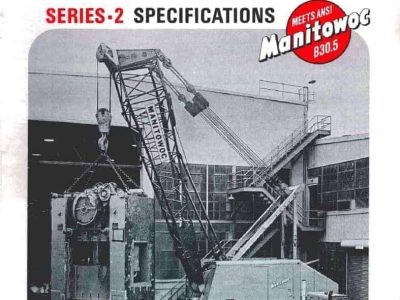

P&H 8100A-TC

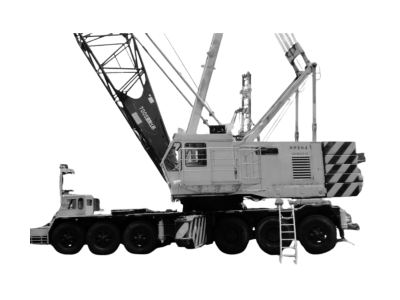

The P&H 8100A-TC is a 91-ton class lattice boom truck crane engineered for heavy lifting and high-reach operations. Featuring an 8×4 carrier, hydraulic outriggers, and P&H’s signature Magnetorque clutch system, the 8100A-TC offers excellent stability, durability, and precision, making it suitable for large-scale infrastructure and construction tasks.

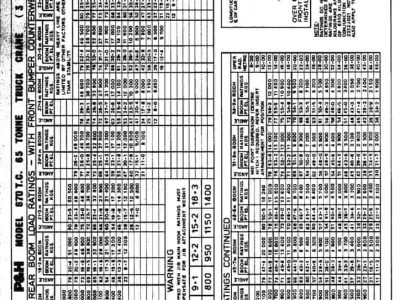

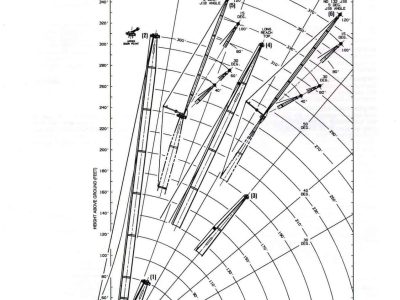

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

The P&H 8100A-TC is a high-performance truck-mounted lattice boom crane developed to meet the demanding needs of modern heavy lifting. With a lifting capacity rated at 91 tons (approximately 82.5 metric tons), this crane was designed as a reliable workhorse for large-scale civil, industrial, and infrastructure projects.

This model shares its platform with the more powerful 127-ton P&H 9125-TC and features the same robust 8×4 truck carrier configuration, offering both mobility and stability. The carrier is built with a high-strength boxed frame to ensure maximum torsional rigidity, vital for safe and consistent operation under heavy lifting conditions. Twelve wheels with four-wheel drive provide excellent traction and mobility over paved and semi-rough terrain, making it suitable for job sites where flexibility is crucial.

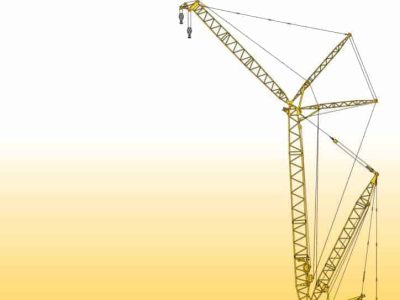

The crane’s superstructure is compact yet powerful, utilizing a planetary hoist system with a dual planetary gearbox for the boom hoist. This arrangement delivers smooth and controlled lifting and lowering, even under load. The boom hoist and load drum assemblies feature internal expanding band-type clutches and full-wrap braking systems for fail-safe operation.

A standout feature of the 8100A-TC is the Magnetorque clutch system, a hallmark of P&H engineering. This system provides precise rotational control with shock-free engagement, which is critical for safe and accurate handling of large loads. Combined with the planetary hoist and drum control, it ensures inching-level precision during both hoisting and lowering operations.

The crane is equipped with a tubular lattice boom constructed from round high-strength alloy steel members. Boom sections are pin-connected for easy assembly and transport. The boom can be extended with optional inserts to meet various lifting and reach requirements. A jib can also be added for additional versatility in high-reach or offset lifting applications.

Hydraulic outriggers are deployed via switch controls and provide full lateral and vertical support, allowing the crane to maintain level positioning even on uneven terrain. The outriggers are designed to be strong enough to handle full-capacity loads, ensuring safety during operations.

Operational controls are arranged for simplicity and responsiveness, with ergonomic levers and switches placed for ease of access. The operator’s cab is fully enclosed and climate-protected, offering safety glass, insulation, and a wide view of the working area. Additional safety features include a boom angle indicator, hoist limiters, and boom backstops.

Designed with low maintenance in mind, the upper machinery layout is open and easy to service, with grouped components and minimized routing of lines and cables. The engine and hoist components are easily accessible for routine inspection and repair.

The P&H 8100A-TC stands out in its class not just for its lifting capacity but also for its balance of rugged durability, operator comfort, and precise control. It is ideally suited for users seeking reliable, cost-effective performance in demanding lifting scenarios where safety, ease of setup, and maneuverability are key priorities.

Latest News

Top 10 Largest Rough Terrain Crane In The World

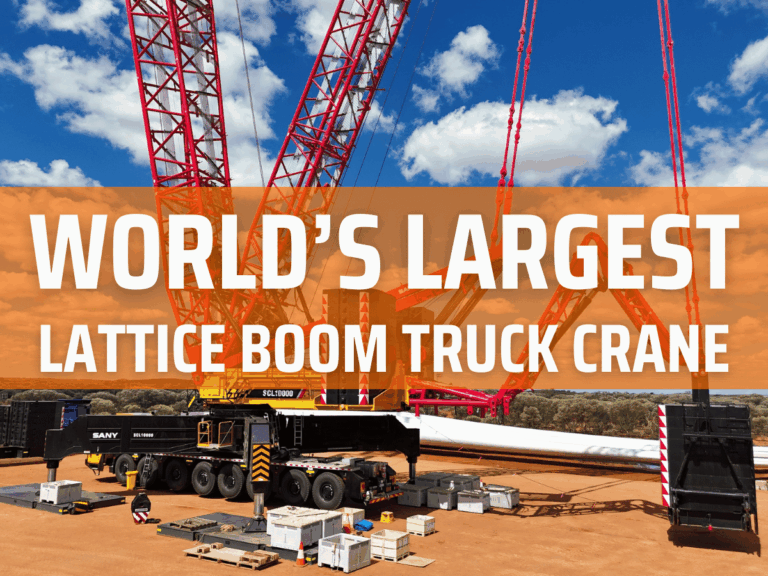

Top Largest Lattice Boom Truck Crane In The World

1 review for P&H 8100A-TC

Ashutosh yadav –

Ok