Link-Belt HTC-25

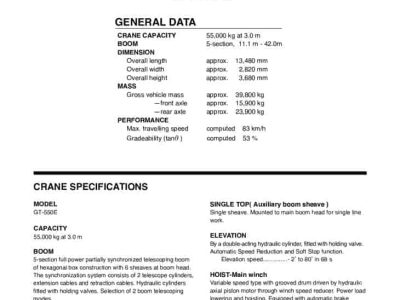

The Link-Belt HTC-25 is a 25-ton truck-mounted hydraulic crane engineered for efficiency and mobility in light to medium-duty lifting applications. Built on a 6×4 carrier chassis, it features a three-section boom extending up to 70 feet (21.34 m), with optional jib configurations providing a maximum tip height of 115 feet (35.05 m). Powered by a GM 6V53 or Cummins VT-555 engine, the HTC-25 delivers dependable lifting performance with flexible configuration options.

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

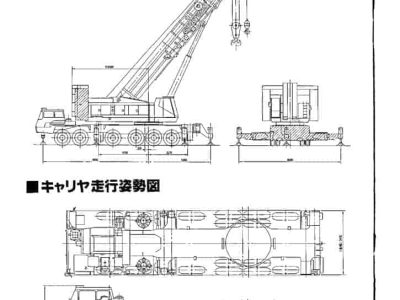

The Link-Belt HTC-25 hydraulic truck crane is designed to serve a wide range of construction, utility, and industrial applications where maneuverability and consistent performance are essential. It is mounted on a 6×4 FMC carrier chassis with a width of 8’0″ (2.44 m) and a wheelbase of 193″ (4.90 m). The frame consists of a welded, double-box section with formed channel main beams and built-in steel outrigger boxes, providing high structural integrity and durability.

At the core of its lifting capability is a fabricated, box-type three-section hydraulic boom that extends from 25′ (7.62 m) to 70′ (21.34 m), utilizing two double-acting telescoping cylinders. The boom sections telescope within one another, guided by wear shoes, and are supported both vertically and horizontally. The boom speed allows for full extension in 35 seconds, with a hoist range from -5° to 75° achieved in 29 seconds. The boom is controlled via a mechanical angle indicator and an optional boom length transducer system.

For increased height and reach, the HTC-25 offers jib options including a one-piece or two-piece 25′ (7.62 m) jib and an optional 45′ (13.72 m) three-piece jib. The 45′ jib consists of a 5′ (1.52 m) base section and a 20′ (6.10 m) straight section, allowing it to be mounted in-line or at a 7.5° offset. Jib configurations can be stowed folded and pivoted to the side of the boom base section when not in use, maximizing transport efficiency.

The crane’s lifting power is driven by two-speed wire rope hoist drums with clutch engagement via the Speed-o-Matic system. These drums allow for smooth, controlled lifts and can also be operated in free-fall mode using a foot-operated brake. Each drum uses 9/16″ (14.29 mm) Type “N” wire rope, with the main hoist rated at up to 11,740 lbs (5,325 kg) line pull using 2-shoe clutches. Maximum line speeds reach 525 f.p.m. (160.02 m/min), ensuring quick lifting cycles.

The hydraulic system includes a triple gear pump delivering up to 50 g.p.m. (189.3 liters/min) at 2,800 rpm, providing fluid power to all crane functions including boom hoist, swing, telescoping, outrigger control, and load-handling systems. The Speed-o-Matic control system is a dedicated hydraulic clutch arrangement offering smooth engagement of winches and hoist drums, with a maximum system pressure of 2,800 psi (193.5 kg/cm²). Relief valves, accumulators, and load-holding valves ensure system stability and safety under heavy loads.

Two engine choices are available for the HTC-25: the GM 6V53, a 6-cylinder 2-stroke diesel delivering 216 hp at 2,800 rpm and 440 ft-lbs (596.81 Nm) torque, or the Cummins VT-555, an 8-cylinder 4-stroke diesel producing the same horsepower with 445 ft-lbs (603.5 Nm) torque at 1,900 rpm. These engines are coupled with an Eaton Roadranger RT613 13-speed transmission, which includes a 3-range auxiliary gearbox with 5-speed main box. Travel speeds range from 2.83 mph (4.55 km/h) in low gear to over 65 km/h (40+ mph) in high gear, depending on the transmission and engine configuration.

The crane’s swing system uses a planetary gear reducer connected to a hydraulic motor, allowing full 360° rotation at up to 3.5 rpm. Counterweights consist of cast iron and steel plate configurations totaling up to 3,600 lbs (1,633 kg) for optimal stability during operation. The outrigger system is fully hydraulic, with control jacks and beams located conveniently within the operator’s cab.

Both the operator’s cab and the upper machinery cab are designed with functionality in mind. The operator’s cab is offset for improved visibility and includes full instrumentation, safety switches, weather sealing, and heater systems. The upper machinery cab is accessible via a three-door enclosure and houses all primary lifting systems.

The Link-Belt HTC-25 combines practical design with efficient lifting performance, making it a reliable option for smaller crane fleets or job sites where compact footprint, transportability, and quick setup are essential.

Latest News

Top 10 Largest Rough Terrain Crane In The World

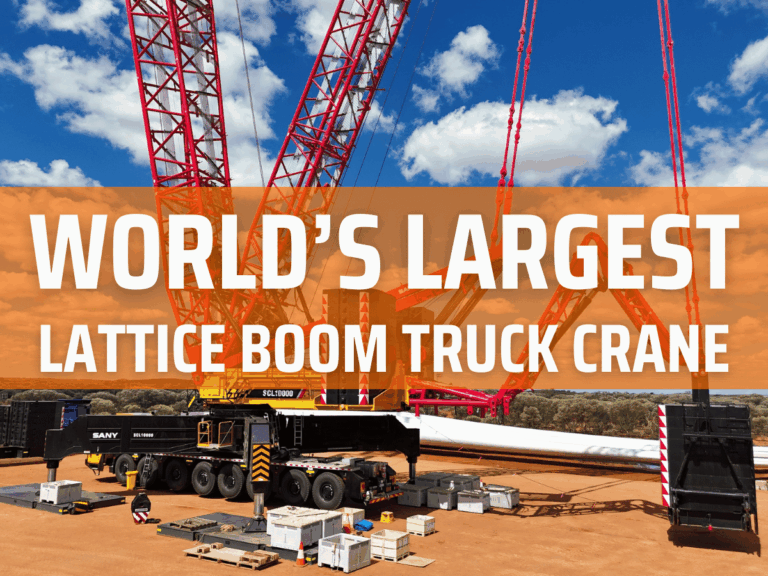

Top Largest Lattice Boom Truck Crane In The World

Reviews

There are no reviews yet.