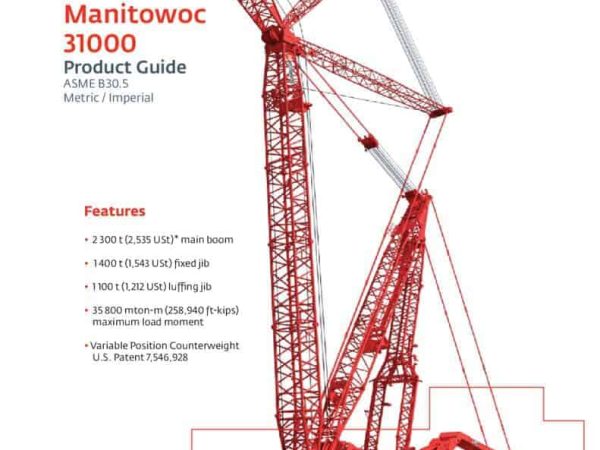

Manitowoc 31000

The Manitowoc 31000 is a 2,300-ton capacity crawler crane, introduced in 2008, and known for its revolutionary Variable Position Counterweight (VPC) system. With a main boom up to 105 metres and a luffing jib of 102 metres, it delivers unmatched lifting performance and versatility, ideal for ultra-heavy industrial projects.

Download Load Chart Here

*Crane Specifications, Load Charts, and Crane Manuals are for reference only.

Contact the crane manufacturer for manuals to operate the crane properly.

Product Description

The Manitowoc 31000 is a monumental advancement in the world of heavy-lift cranes, representing the largest capacity crawler crane ever built by Manitowoc and one of the most powerful in global operation. First introduced during ConExpo 2008, the 31000 was engineered specifically to tackle ultra-heavy lifting applications in energy, petrochemical, and infrastructure sectors, offering not only massive lifting capacity but also remarkable control and efficiency.

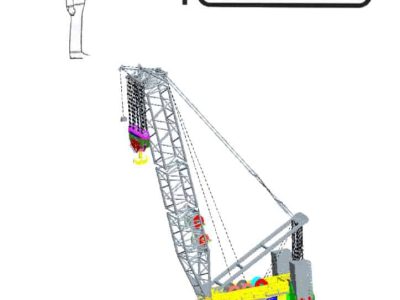

At the heart of the Manitowoc 31000’s innovation lies its Variable Position Counterweight (VPC) system — a game-changing technology developed to enhance lifting efficiency and mobility. Unlike traditional fixed or trolley-mounted counterweight designs, the VPC automatically adjusts the counterweight radius during lifts, using a hydraulic arm to move the suspended counterweight from 8.4 metres out to nearly 29 metres. This dynamic adjustment maintains optimal load balance throughout the crane’s entire working envelope and keeps the load centre within the crane’s 17 x 20 metre footprint. The benefit? Full pick-and-carry capability at 2,300 tonnes, improved site mobility, and significantly reduced ground preparation — a major cost saver on job sites.

The Manitowoc 31000 features a maximum main boom length of 105 metres and a luffing jib of up to 102 metres, providing exceptional height and reach. The maximum boom + jib combination is 90 metres main boom plus 102 metres luffing jib, giving a staggering maximum lifting height of almost 200 metres. This flexibility allows it to handle large components in refineries, modular construction projects, and energy facilities with ease.

The first production unit of the Manitowoc 31000 was delivered in April 2013 to Chunjo Construction of South Korea. The crane made its debut at a Posco E&C-operated plant in Gwangyang, where it was involved in a high-tech project converting low-grade coal into liquefied gas. The 31000 undertook 123 heavy lifts during the course of the project — the first being a 250-tonne lift using a 55-metre main boom and 60-metre luffing jib.

Its most notable performance on this project was a pick-and-carry lift of a 650-tonne cold box, one of the largest components on site. The 55-metre tall cold box, measuring 9 x 9 metres, was first lifted in tandem with a 600-tonne Manitowoc 18000. Once the load was upright, the 31000 continued the operation solo, carrying and placing it in its final location. Despite spatial constraints, including a nearby wall limiting slewing radius, the crane completed the task efficiently by raising the boom to its highest angle, reducing swing, and maintaining stability — a clear demonstration of the VPC system’s benefit.

The VPC’s suspended counterweight design not only eliminates the need for large wheeled trolleys, but also allows lighter crane mats and tighter work zones. This feature reduces the amount of site preparation needed and makes the crane suitable for even congested industrial environments.

From a technical perspective, the Manitowoc 31000 stands out for offering:

- Maximum lifting capacity: 2,300 tonnes

- Main boom: Up to 105 metres

- Luffing jib: Up to 102 metres

- Max boom/jib combo: 90 + 102 metres (approx. 200m height)

- VPC system for auto-adjusting counterweight radius (8.4–29 metres)

- Pick-and-carry rated for full capacity within crane footprint

Designed from the ground up with advanced hydraulics, control systems, and rigging innovation, the Manitowoc 31000 is not just a crane — it’s a heavy lifting system that reshapes what is possible on complex construction sites.

Whether it’s lifting refinery modules, LNG cold boxes, nuclear reactor components, or massive infrastructure segments, the Manitowoc 31000 combines raw power with smart engineering — a fitting flagship for the Manitowoc name.

Latest News

Top 10 Largest Rough Terrain Crane In The World

Top Largest Lattice Boom Truck Crane In The World

Reviews

There are no reviews yet.